info@krishavintl.com

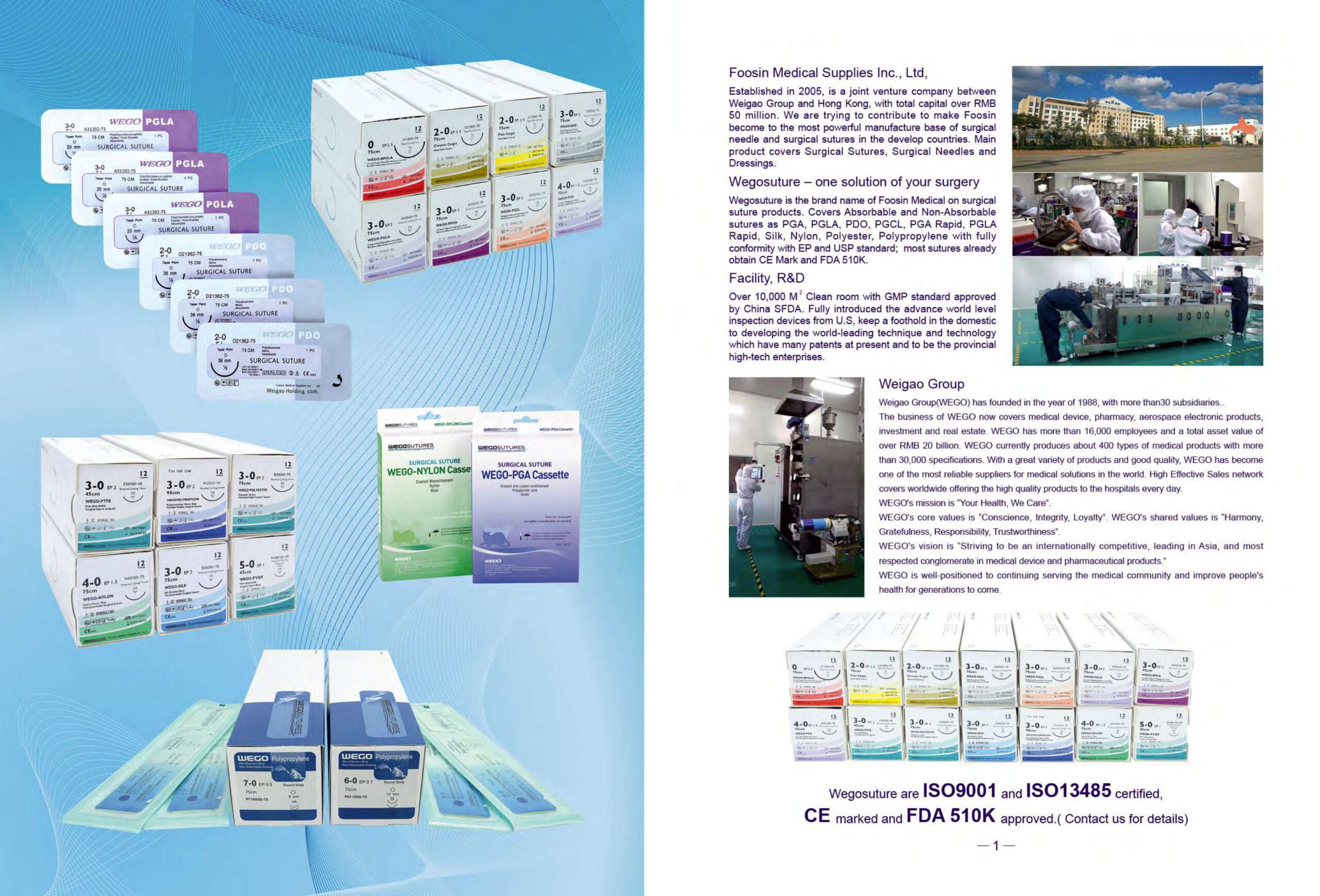

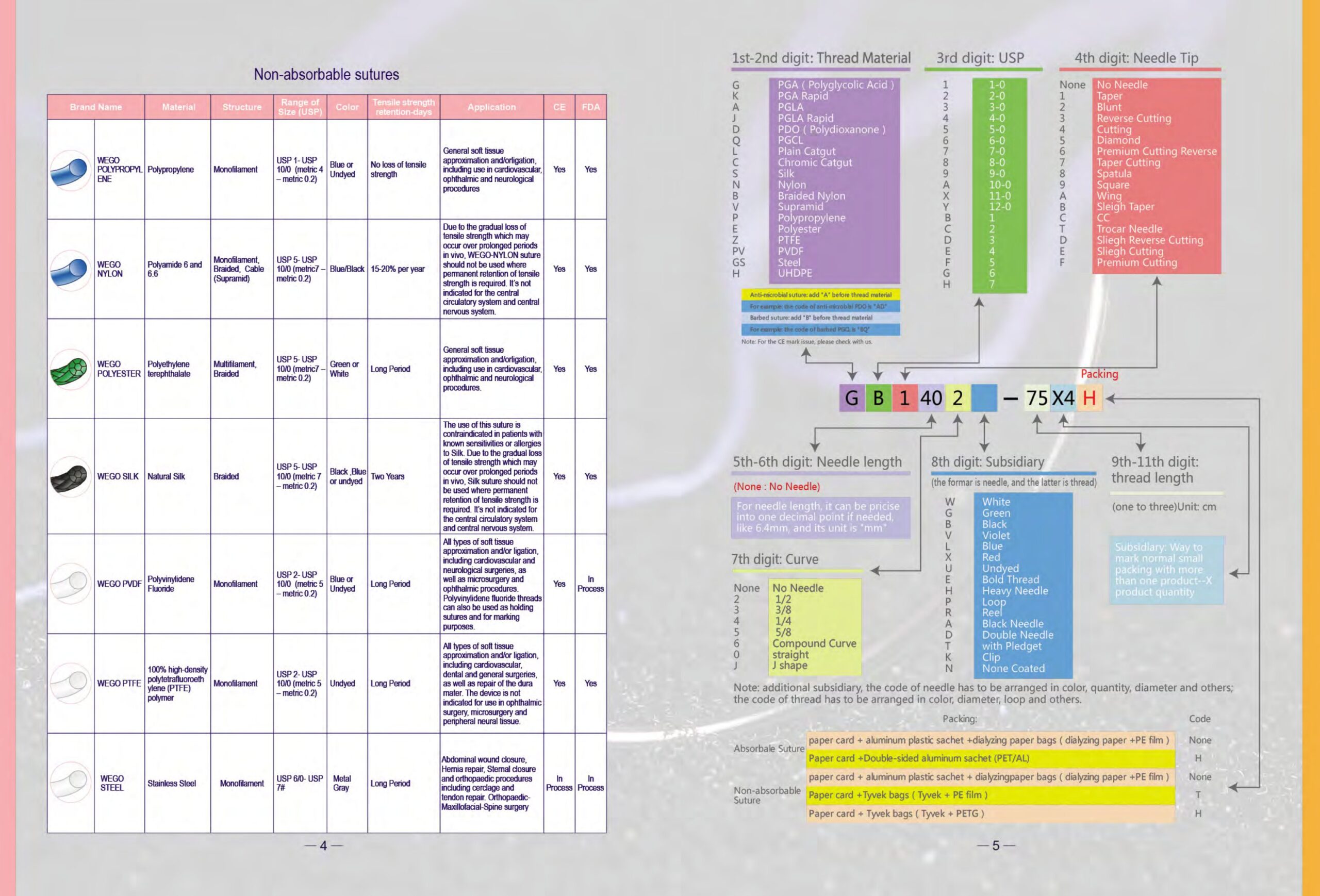

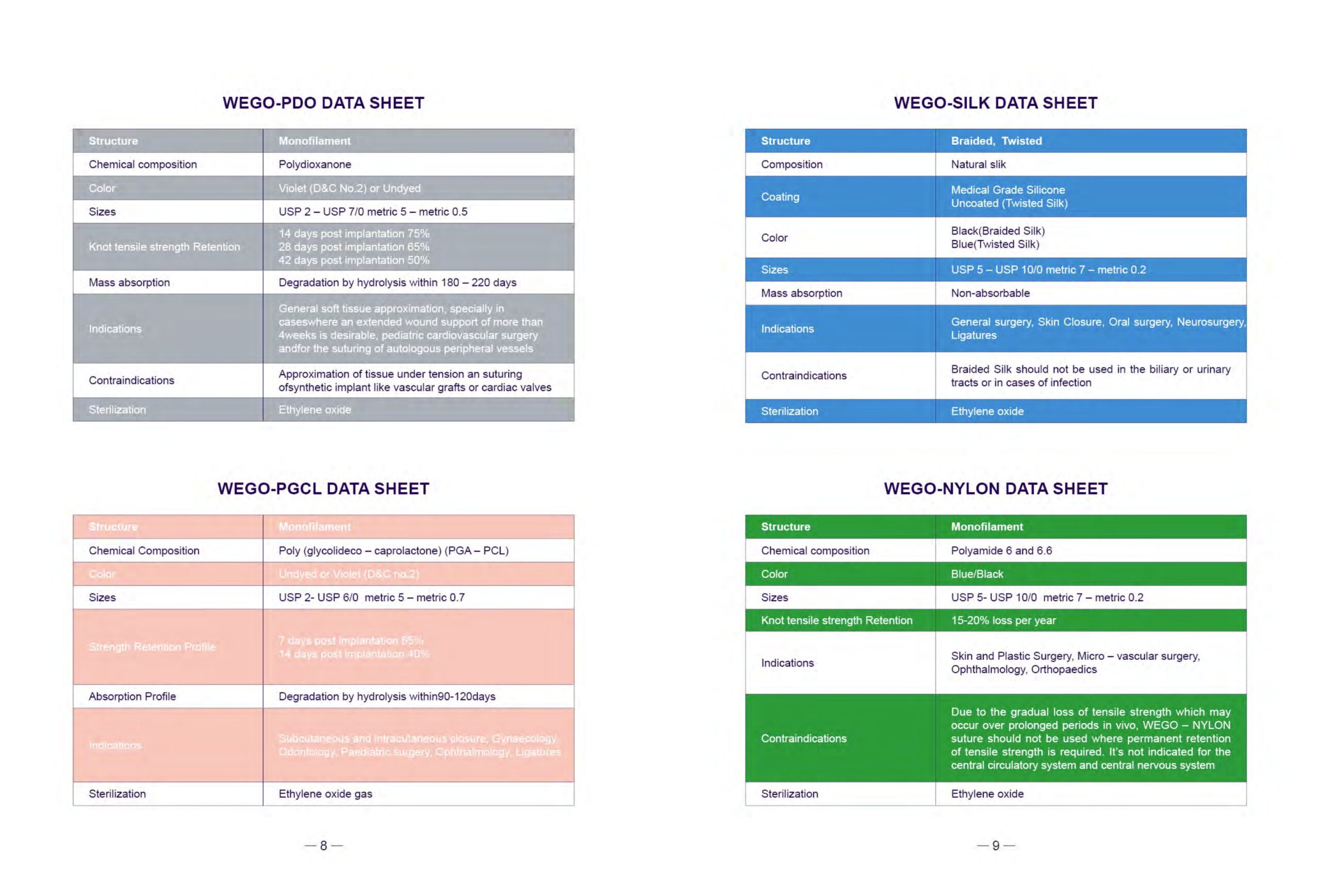

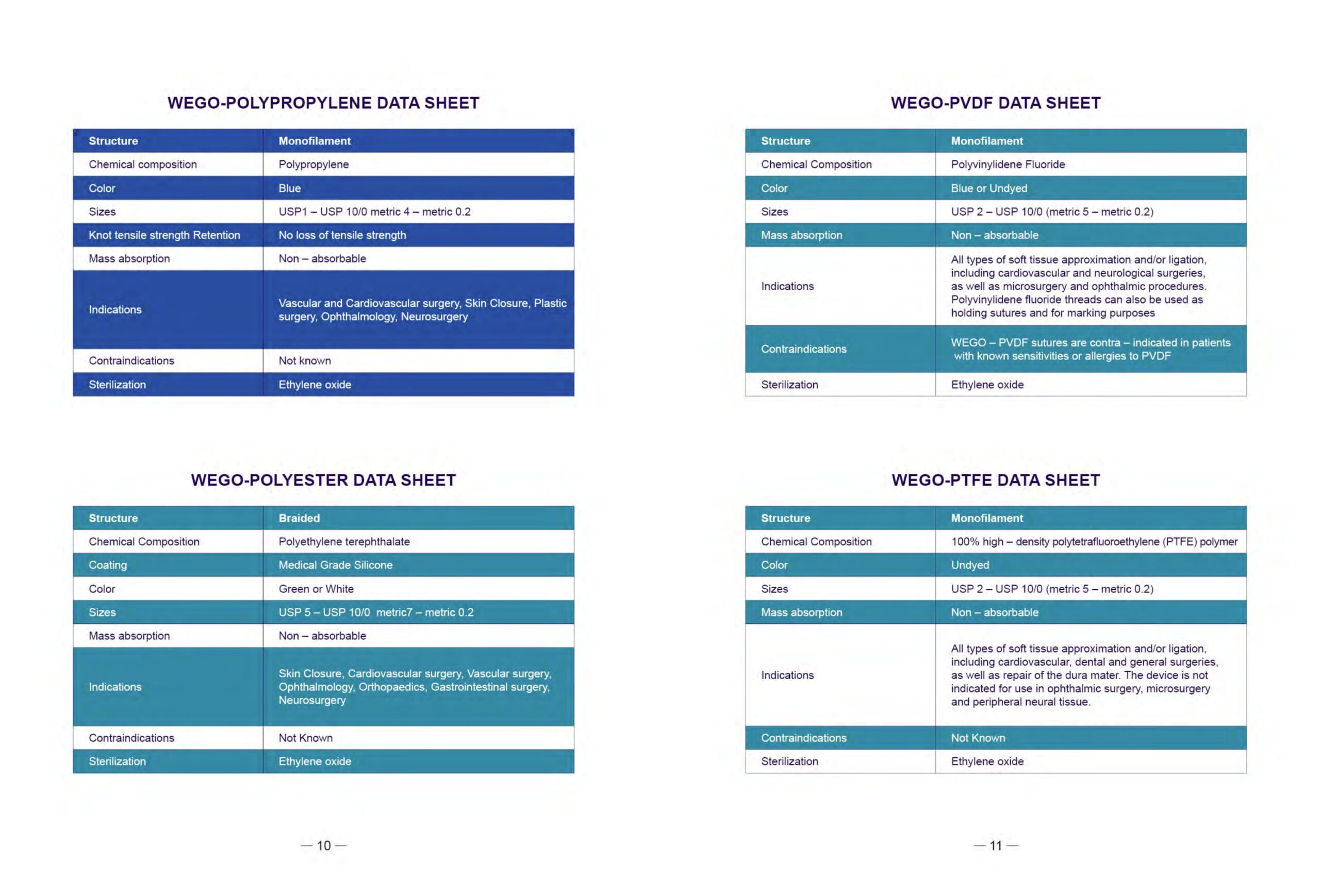

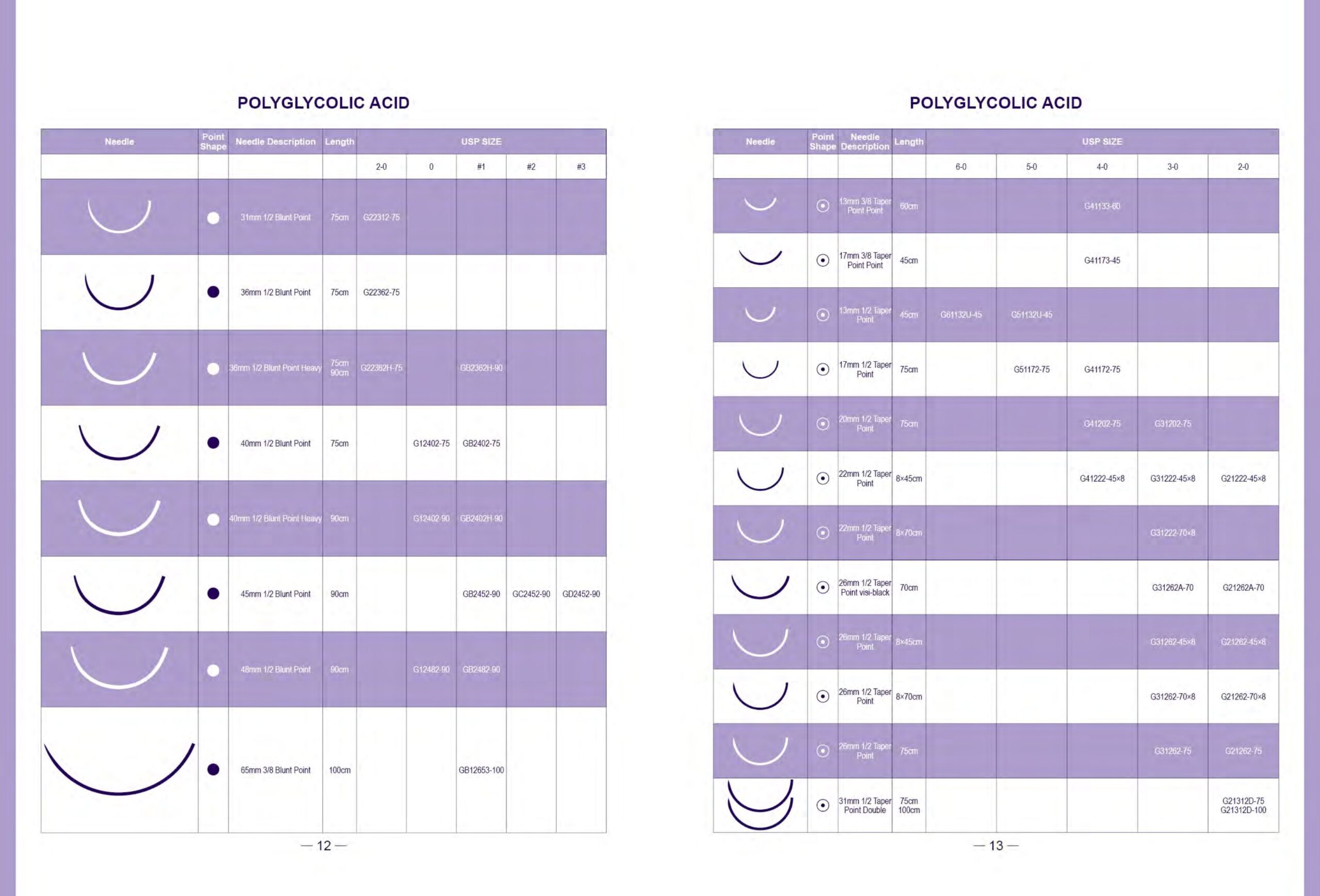

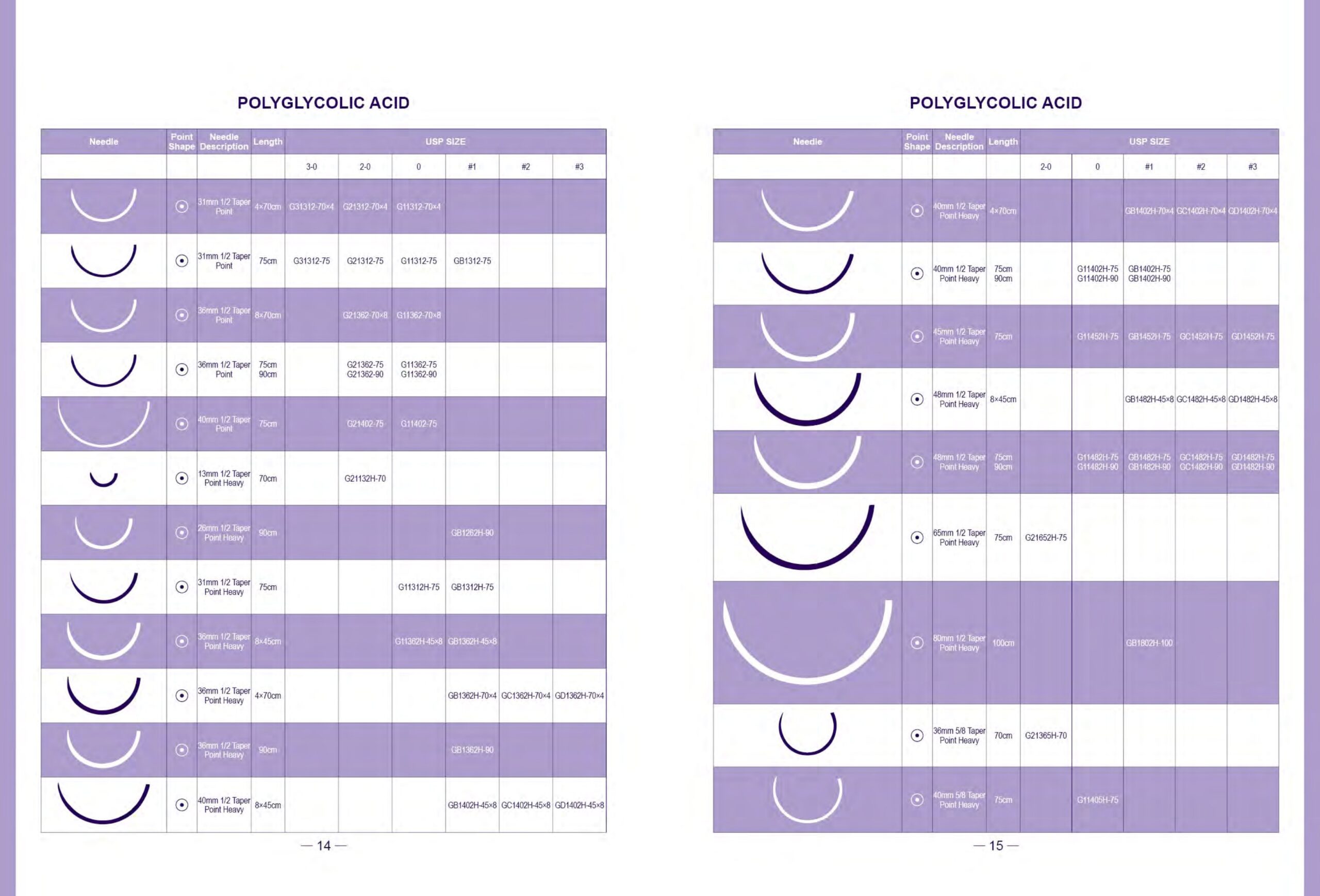

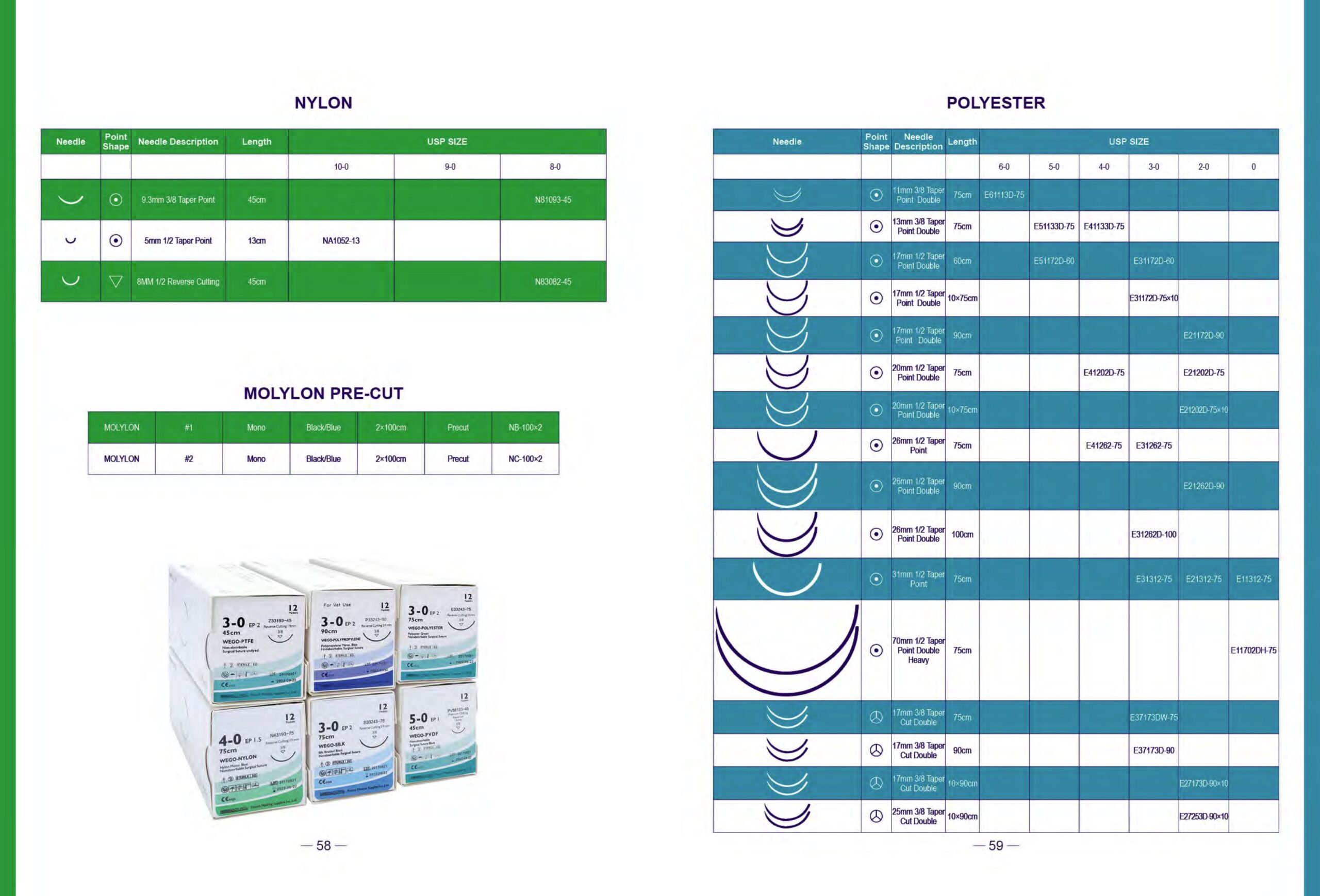

Sterilized surgical sutures are medical devices used to close wounds and surgical incisions. These sutures are made from various materials, such as silk, nylon, polypropylene, or gut, and come in a variety of sizes and shapes depending on their intended use.

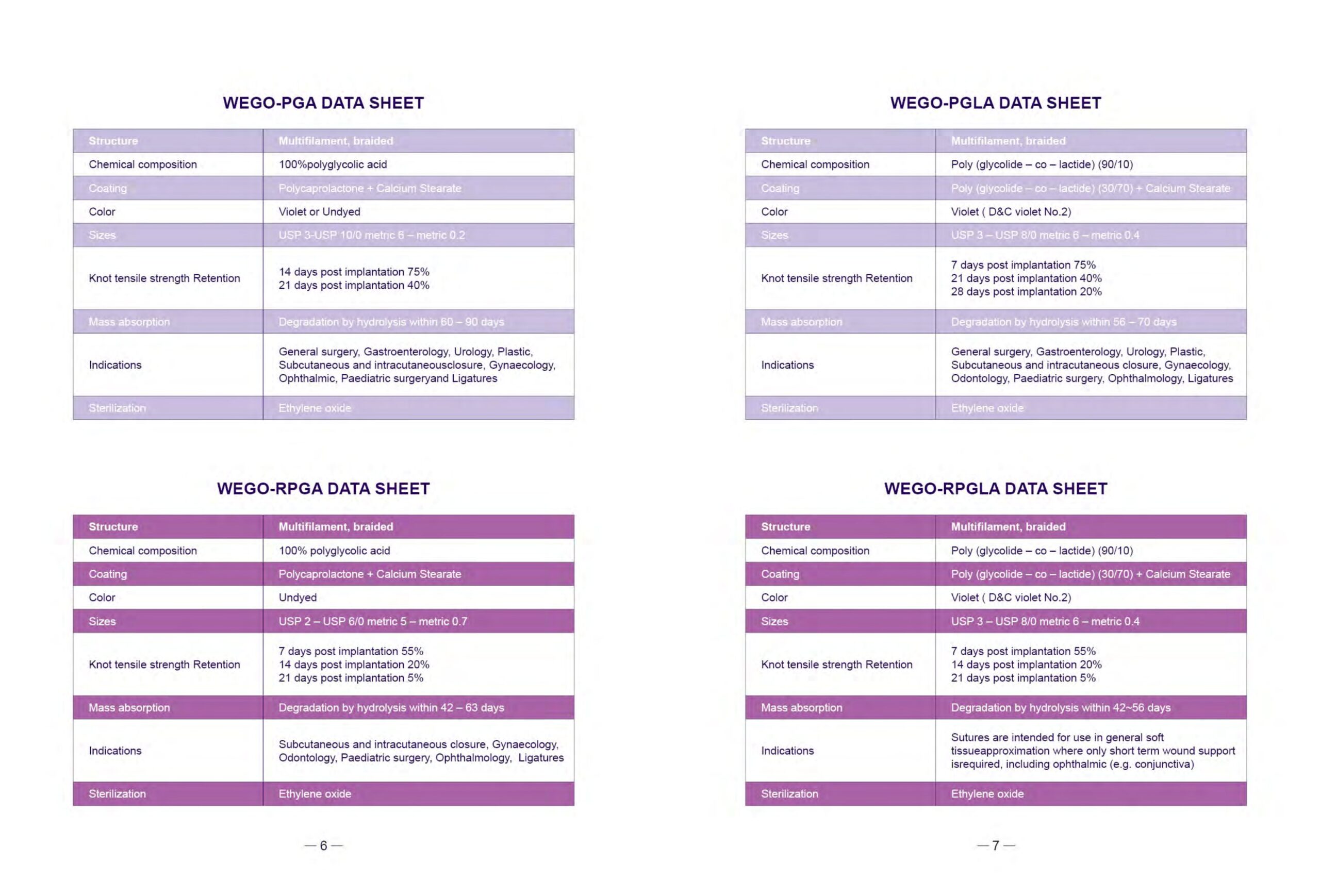

Sterilization is a critical step in the manufacturing of surgical sutures to ensure that they are free from harmful microorganisms that could cause infections in patients. The most common methods of sterilization for surgical sutures include ethylene oxide (EtO) gas, gamma radiation, and electron beam radiation.

After sterilization, the sutures are typically packaged in a sterile environment and labeled with information about the material, size, and lot number for tracking purposes. The packaging also provides a barrier to prevent contamination of the sutures before use.

During a surgical procedure, the surgeon will use a needle attached to the suture material to sew the wound or incision closed. The sutures are left in place for a specified amount of time, depending on the type of suture material and the location of the wound, before being removed.

Overall, sterilized surgical sutures play a crucial role in wound closure and healing, and their safe and effective use relies on proper manufacturing, packaging, and handling.